Removal of Silica, Pre-treatment for R/O, waste water, heavy metals, applications such as: Food, Power plants, Chemical, Petro Chemical, Pharmaceutical, Mining, Beverage, Dyeing, Oil, Leachates etc.

EEC for Leachate in China

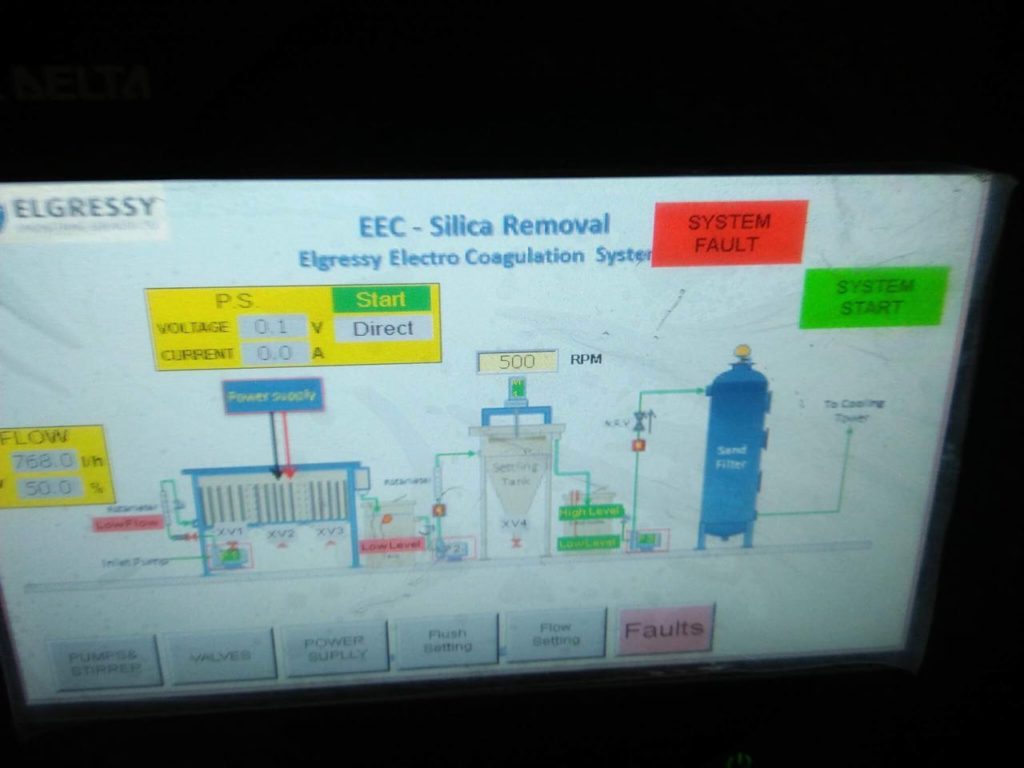

EEC for Silica removal

at Eagle Cement in the Philippines

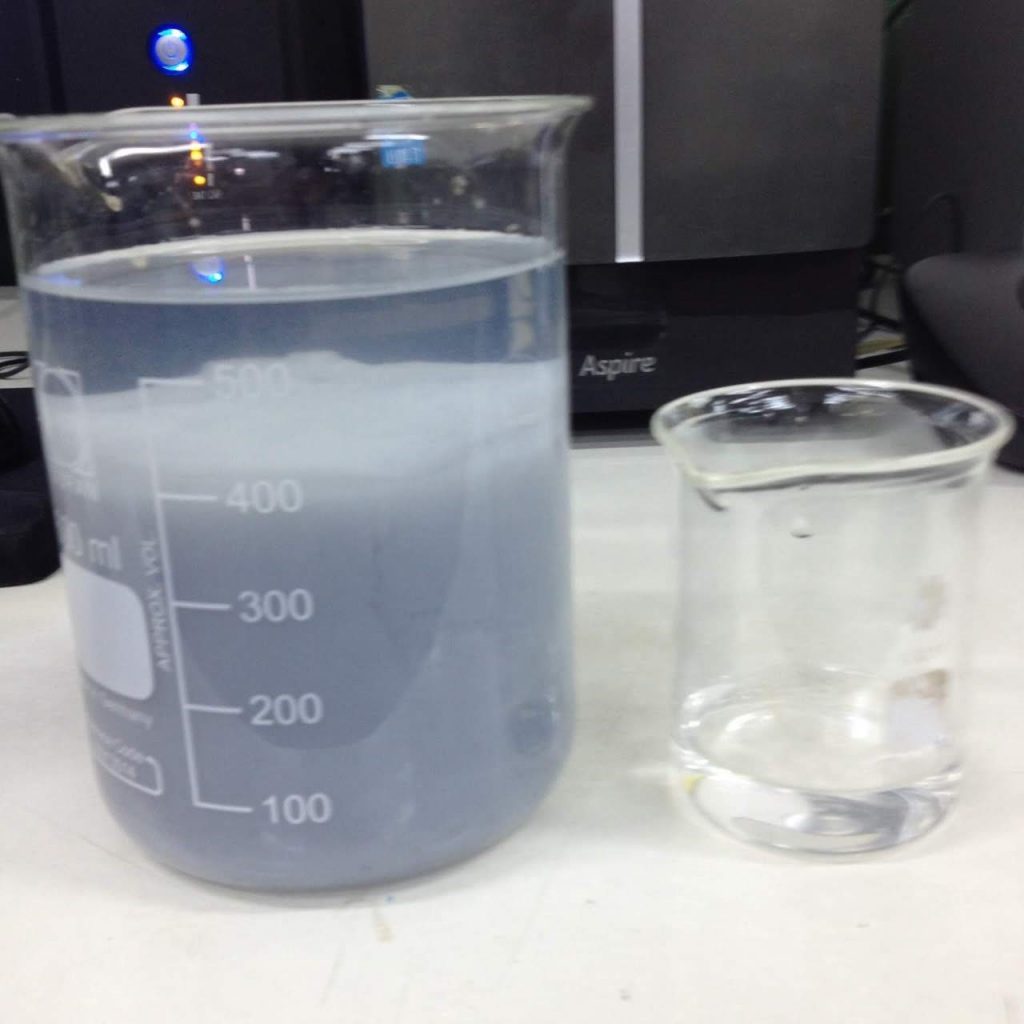

B4 EEC treatment 180 ppm Silica after EEC Silica removed to 8 ppm.

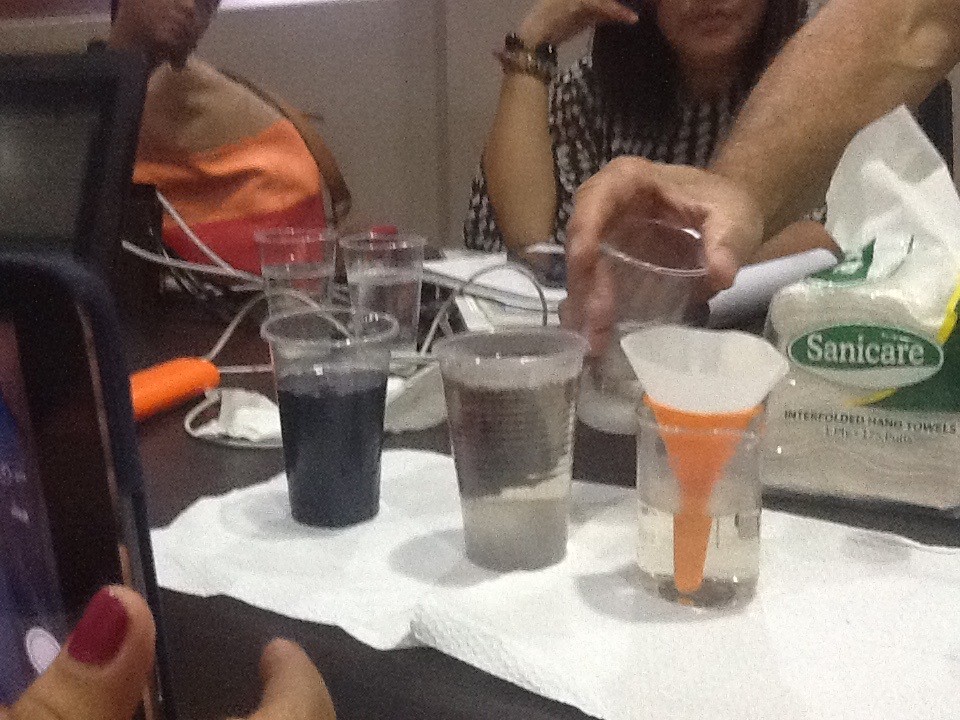

Blue dyed waste water after EEC treatment clear re-usable water

EEC is a modular fully automatic Green and Clean side stream installed solution for many applications.

Flow sizes from small to large. Small footprint, low energy and low maintenance, low recurring cost, in most cases water is re-usable for irrigation even processes, please see PRESENTATION and Brochure or contact us right away.

EEC and EEO

Electrocoagulation and Electro-oxidation water and wastewater treatment – EEC/EEO

Electrocoagulation and Electro oxidation water and waste water treatment with EEC and or EEO.

Elgressy is Leader in Electrochemical, Electrocoagulation and Electro-oxidation for Cooling Tower Treatment, water and waste water treatment EEC/EEO, with LPB Legionella Pneumophilia Risk minimization and corrosion prevention for Cold and Hot water systems.

Electrocoagulation and Electro oxidation water and waste water treatment with EEC / EEO

Elgressy electrocoagulation and Electro oxidation systems efficiently separate and remove contaminants from water and waste water, without using chemical additives or generating hazardous byproducts.

Revolutionizing water treatment:

EEC/EEO utilize proprietary electrodes and components to substantially remove multiple impurities from water,

wastewater and rivers.

These include:

various heavy metals, metalloids, silica, organics, ammonia, nitrates, nitrites, phosphates, emulsified oils, suspended solids, solid particles, dye, arsenic, radioactive isotopes and even pathogens.

Innovative technology designed to meet your needs

Elgressy custom manufactures/taylor makes the EEC/EEO systems according to the varying concentrations of contaminants and the clients desired result. Factors such as current density, pH, electrode type, retention time, etc. are key factors in determining the system size, shape, metals, surface area and configuration.

Elgressy proprietary electrodes are manufactured to target a specific or broad range of contaminants in water and

offer a high surface area to volume ratio. As a result, ionization efficiency of the electrode is superior, making the electrocoagulation process effective, energy efficient and quick.

The EEC/O systems allow for immediate treatment without chemicals, significantly improve operations, reduce overall

treatment costs, and help meet increasing environmental regulations.

Advantages:

- “industrial grade” – Small Footprint/minimal attention and service required.

- Chemical free – no hazardous byproducts are generated during the process and no chemical additives are required.

- Low Capital Cost – EEC/EEO systems generate substantial savings over current operations.

- Low Operating Cost – Operating costs can be dramatically reduced by smoother operations and elimination of reagent chemicals and polymer consumption.

- Proprietary components.

- Simple to retrofit.

- Large electrode surface area enables improved reactions.

- Effective for a broad range of impurities with the ability to target specific contaminants.

- Scalable – 1m3/h – 100m3/h and more as systems are modular.

- Minimal electrode material and energy consumption.

- Simple electrode replacement.

- Peace of Mind – Comply with current and future regulations.

- Reduced Salts in Effluent-Low or no use of reagents reduces the sodium, sulfates and chlorides in the effluent.

- Lower Sludge Quantities – significantly less sludge is produced resulting in lower disposal costs.

.

Follow Us!